In an ever more demanding market where quality products are used and turnaround needs to be shorter, Phoenix Metalform offers innovative and highly accurate turret punching solutions.

Our team uses state of the art turret punching up to 30 tonne capacity to produce components that are cost effective and accurate for a variety of production runs. Our turret punching offers advantages with it’s best feature being versatility. Our team are able to assist you with a quick turn around using top of the line CNC turret punching to offer a variety of designs for small to large scale jobs delivering accuracy for your specification for mild steel, stainless or aluminium.

Our high volume capacity can help produce a low cost solution for your product needs along with delivering accuracy for your project specifications. Phoenix Metalform will reduce your turret punching costs and in turn, improve your productivity and the cost of your final product.

Our range of turret punching for sheet metal includes ceiling panels, fencing and gate infill panels, balustrade panels, sunscreens, wall panels, scaffold planks, stair treads, filters, building facades, architectural feature panels and custom perforations.

Our state of the art CNC Turret Punches produce highly accurate components and are very cost effective for both short and long production runs. Due to high volume capabilities we can offer reduced lead-times. With an extensive tooling library we are able to produce a limitless range of complicated shapes in a variety of materials and thicknesses.

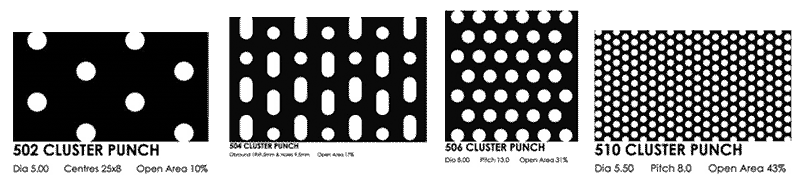

Our range of perforated products for sheet metal punching include: